Timelines

From the standpoint that both LCD and more recently OLED have become mainstays of the display space such decisions should be easier than when speculating about whether a new technology would ever become large enough to justify anticipatory spending in the billions of dollars, but that is not the case. There are many relatively new factors that make decisions about capacity timelines far more granular than they were years ago, and more aggressive technology development spending has added to the potential for capacity adjustment errors. China has been a major factor in changing the capacity risk profile for panel producers in that government subsidies have allowed capacity decisions to be less reliant on profitability than is the case for public companies. This has allowed the Chinese display industry to become the dominant player in the LCD display space and still drives what might be considered unbridled expansion even today.

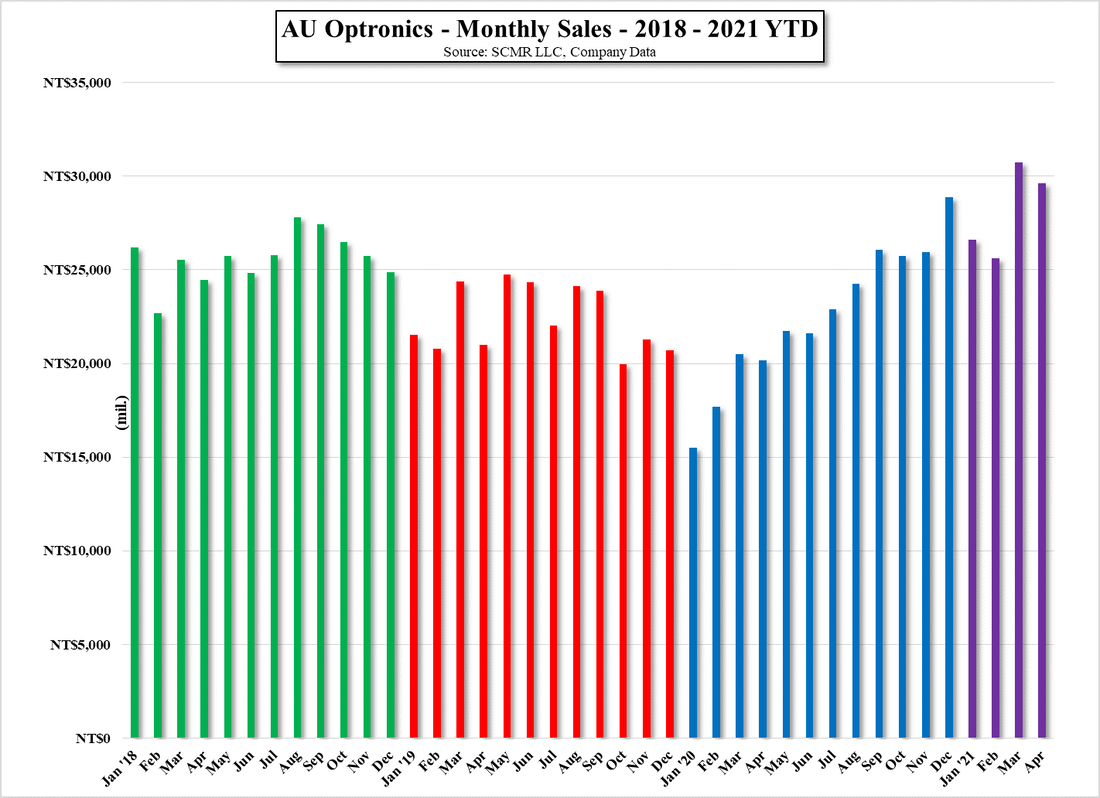

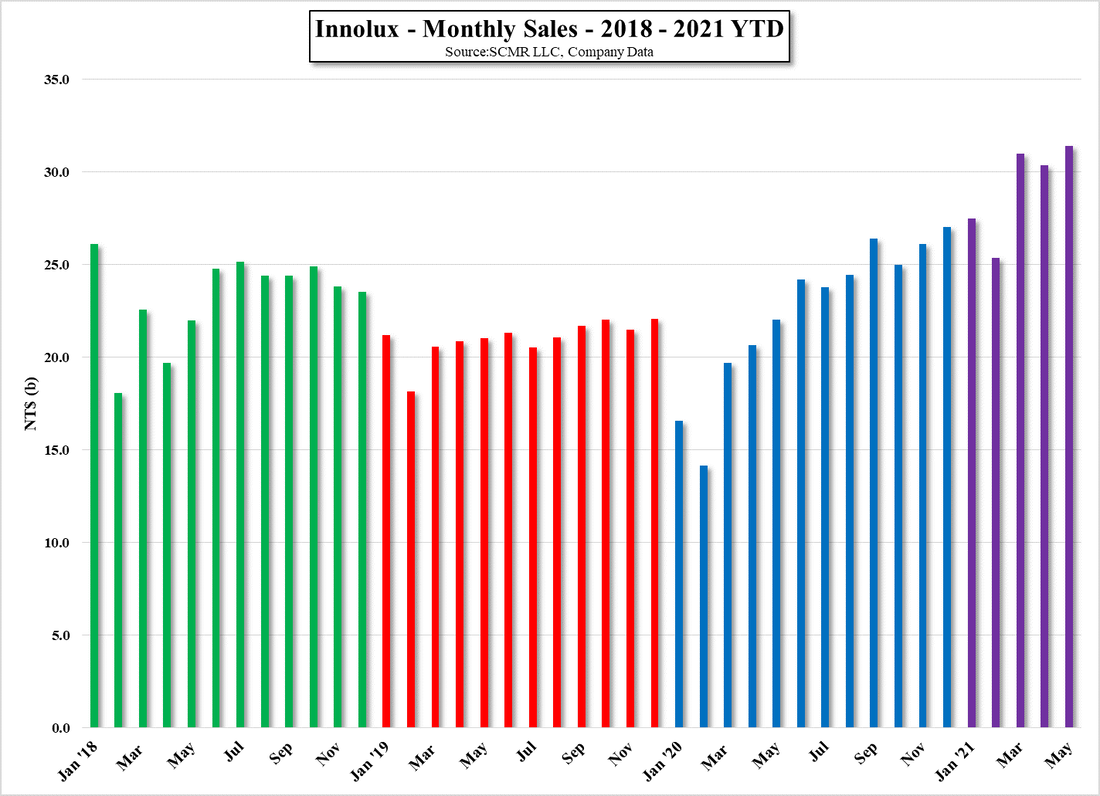

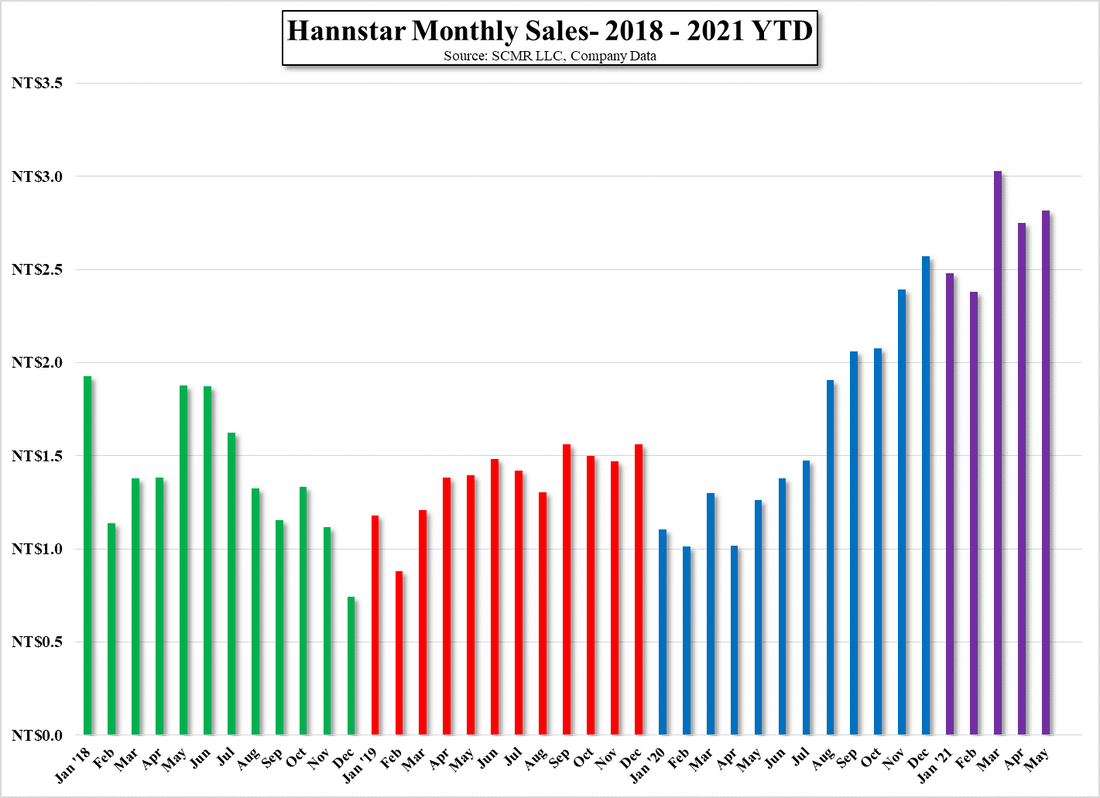

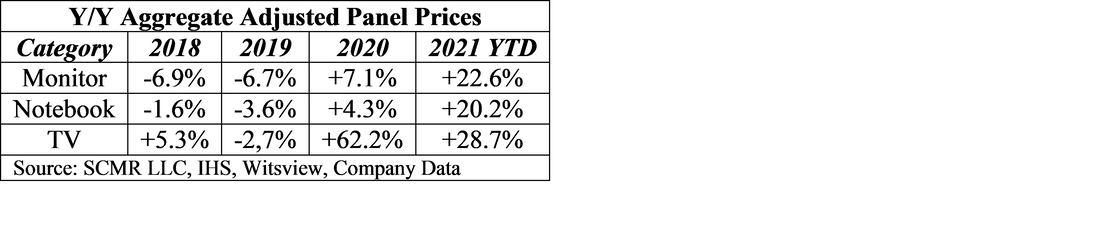

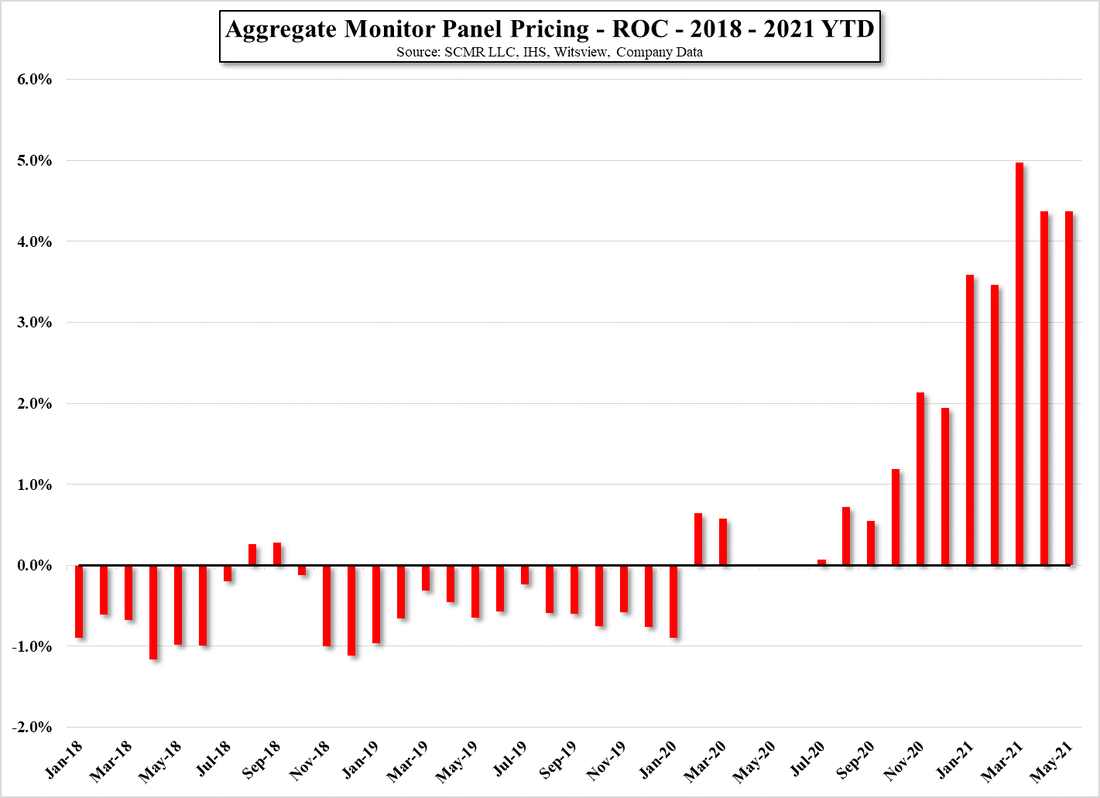

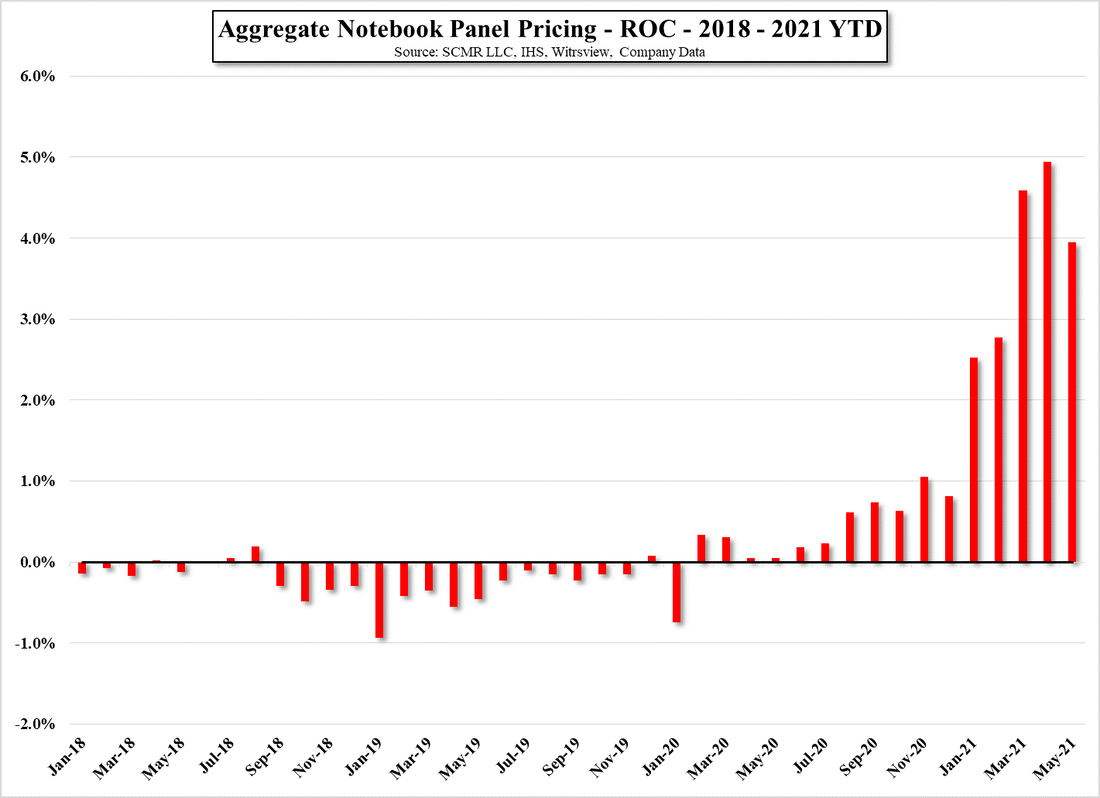

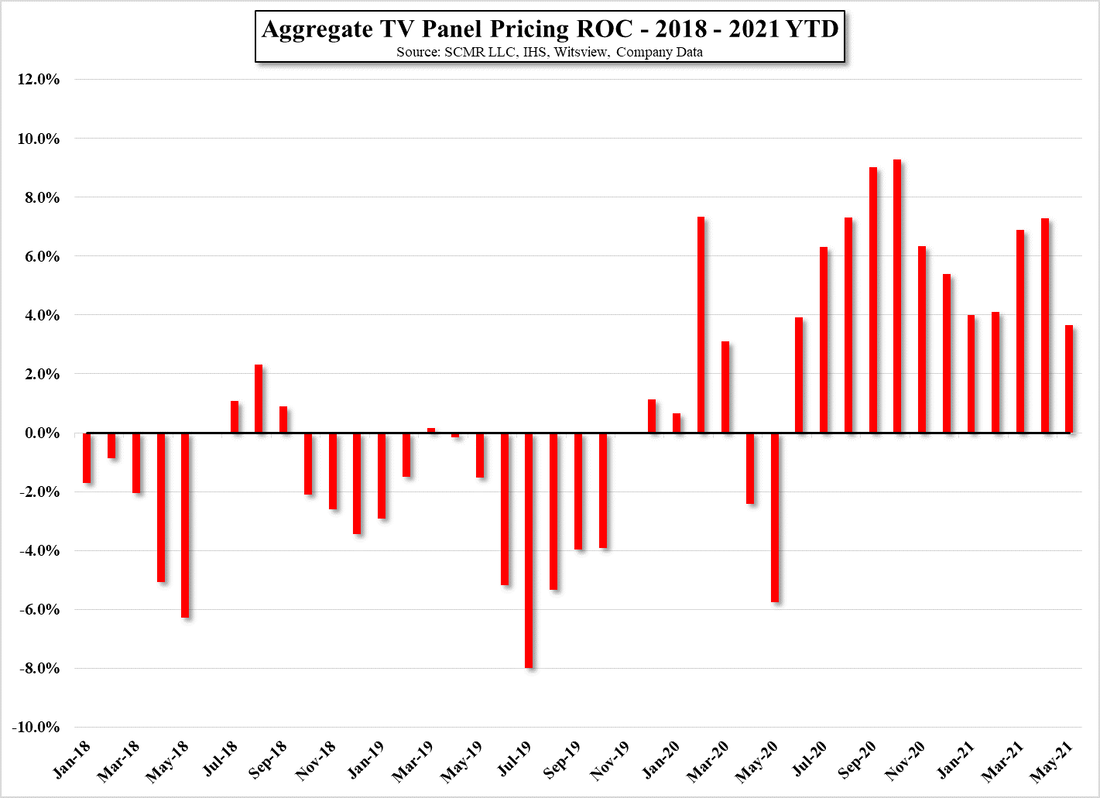

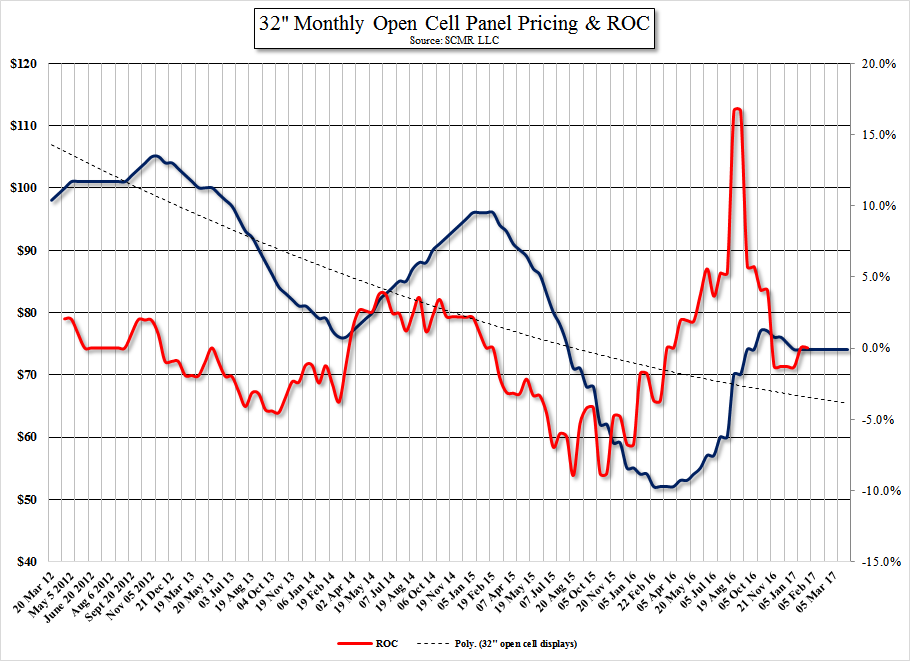

While capacity expansion timelines are based on long-term demand (or should be), they are colored by short-term issues that can put such decisions in a more or less positive light and depending on the experience of the producer those short-term influences can become major selling points for capacity expansion or reduction. Given that panel prices, particularly large panel prices, have been rising for the last year, less experienced panel producers can begin to feel that they can remain profitable continually, while others feel that such price increases are a possible warning sign and take a more conservative approach to expansion. Underlying all of these decisions however is the question as to how long each display technology will be sustainable, and how will new technologies affect existing display capacity.

LCD was a disruptive technology to say the least, essentially ending the reign of the Cathode Ray Tube, but plasma displays, the first self-emitting display technology, were also thought to be a technology that would eventually replace LCD about 20 years ago. However after peaking around 2010, plasma displays have all but disappeared, especially when Samsung, the leader in the TV market, pulled the plug on the technology back in 2014.

OLED has also been touted as an LCD ‘eliminator’, but while it has been the focus of a great deal of capacity spending OLED co-exists with LCD, with each having their pluses and minuses. Quantum dots have been another technology that was also touted as a potential hazard to existing display technologies, particularly OLED, but has found its way into the LCD supply chain, giving the older technology an extended ability to compete with OLED, and could be a help to OLED technology if Samsung Display (pvt) is successful in developing its QD/OLED process.

Micro-LED technology is currently a focus for display development teams, as it too has been touted as the display technology of the future, and spending toward its development has been increasing rapidly, but expectations that new technologies can be so disruptive as to almost immediately replace existing display technology is what marketing teams dream of at night and not particularly practical from a business or financial standpoint. With the billions of dollars already spent on existing technologies, panel producers, while they might spend on development projects to see if a new technology will pane out, are going to favor spending on what they know and can sell, so when we look at timelines in the display space, we do so with a great deal of skepticism, especially having seen those timelines change more often than not over the years.

That brings us to South Korea, where both Samsung and LG Display reside, and while Chinese panel producers such as BOE (200725.CH) and Chinastar (pvt) are the volume leaders in LCD, South Korean panel producers are trendsetters and their capacity decisions can influence the entire industry both positively and negatively. Samsung Display’s exit from the large panel LCD space has been a positive influence on Chinese panel producers and has focused much of their attention on competition between themselves now that they see SDC’s exit from large panel LCD as a positive going forward. Without Samsung to compete with in the space they seem to be expanding LCD capacity to become ‘China’s leader’ in the space, while South Korean producers are focusing more on OLED, which they believe will continue to grow more rapidly than LCD and will also generate premiums that are greater than what they believe can be generated in the more mature LCD space.

Samsung in particular has already begun the conversion of its L7-2 LCD fab to a Gen 6 OLED line, and is expected to begin equipment move in next month. In this case, we expect the conversion will be rather quick, as some of the backplane equipment is being transferred from its A3 fab. As both phases of the L7-2 conversion will be using LTPS equipment from A3, which was converted to LTPO, we expect the first phase to be completed by the end of this year and phase 2 by July of next year. Samsung might be able to ramp these lines faster given their experience and the use of existing equipment, but we take a more conservative approach at least for the next few months.

SDC is also considering the addition of capacity for large OLED panels, meaning notebook and monitor sizes, and has been working with equipment suppliers to develop production equipment for that purpose, but they have yet to decide whether this capacity is necessary or where they might use existing capacity space. SDC has another LCD line L8-2 and is currently offering for sale the equipment from that line, so they have the potential to replace that space with OLED capacity, or they can convert some existing small panel OLED capacity to the larger panel sizes, but we expect those decisions to be made later this year, and final decisions on whether to expand the company’s QD/OLED production project are also still to be made.

LG Display (LPL) is also evaluating whether to add OLED capacity for similar IT products as it plans for producing OLED panels for Apple’s (AAPL) iPad next year. While Samsung has been expected to be the provider for the iPad next year, LGD will certainly be a contender for a 2nd spot and will likely need to dedicate new or converted capacity to Apple by 2023, although they currently operate two OLED lines E6-1 and E6-2 with a third line (E6-3) a possibility depending on Apple’s timeline. There has also been some speculation that LGD is considering building a new Gen 10.5 OLED fab, but we believe much of that speculation has been based on the rumors that Samsung Electronics is going to sign a multi-million unit deal with LGD for OLED displays. Given the relatively low probability of that transaction, we have yet to put such a plan in our database.

The decisions for Samsung Display and LG Display as to whether to expand OLED capacity are primarily being driven by Apple’s adoption of the technology. As the iPhone line is all OLED, Apple’s use of the technology in tablets, notebooks, and monitors is a catalyst for increasing OLED penetration, and while expansion of OLED penetration in the smartphone space continues, competition from Chinese OLED producers is also expanding. OLED TV and the use of OLED displays in IT products is where incremental capacity is needed and LGD’s lock on the OLED TV space shifts the focus to small panel OLED. There is no greater asset in that space than Apples potential adoption of the technology through the rest of its product line and we expect OLED capacity decisions will be predicated on Apple’s plans rather than the near-term issues that might affect panel pricing generally, and while we expect Apple to move more slowly than most, their focus on high quality technology leads us to conclude that there is little reason not to expect a continued migration toward OLED, at least until another technology comes along.

RSS Feed

RSS Feed